Send your inquiry: sales@cncdsteel.com

Send your inquiry: sales@cncdsteel.com

Product Introduction430 stainless steel is a universal steel with good corrosion resistance, better thermal conductivity than austenite, smaller thermal expansion coefficient than austenite, heat resistance fatigue, adding stabilized element titanium, good mechanical properties at the weld. 430 stainless steel used for building decoration, fuel burner parts, household appliances, home appliance parts. 430F is 430 steel with free cutting properties, mainly used in automatic lat…

430 stainless steel is a universal steel with good corrosion resistance, better thermal conductivity than austenite, smaller thermal expansion coefficient than austenite, heat resistance fatigue, adding stabilized element titanium, good mechanical properties at the weld. 430 stainless steel used for building decoration, fuel burner parts, household appliances, home appliance parts. 430F is 430 steel with free cutting properties, mainly used in automatic lathes, bolts and nuts. 430LX add Ti or Nb in 430 steel, reduce the C content, improve the processing performance and welding performance, mainly used in hot water tank, heating water system, sanitary appliances, household durable appliances, bicycle flywheel and so on.

It is also known as 18/0 or 18-0 because of its chromium content. Compared with 18/8 and 18/10, it contains slightly less chromium and the hardness is correspondingly reduced.

Grade | 201, 202, 301, 304, 304j1, 304l, 321, 309s, 310s, 2205, 409l, 410, 410s, 420, 420j1, 420j2, 430, 439, 409l, 443, 444, etc |

Standard | ISO, JIS, ASTM, AS, EN, GB |

surface | N0.1, N0.2, N0.3, N0.4, N0.5, N0.6, N0.7, N0.8, 2D, 2B, HL, BA, 6K, 8K, etc |

Thickness | 0.1-200mm |

Width | 10-2000mm |

MOQ | 5MT |

Packaging | Export standard, seaworthy |

Trade Term | FOB, CFR, CIF |

Transport Type | Container, bulk and train |

Loading port | Shanghai, qingdao, tianjin, etc |

Payment terms | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

Delivery time | 15-35 days after confirmed order |

Action of stainless steel

Stainless steel will not corrosion, pitting, rust or wear. Stainless steel is also one of the strongest metal materials used in construction. Due to its excellent corrosion resistance, stainless steel enables structural components to maintain permanent engineering design integrity. Chromium-containing stainless steel also combines mechanical strength and high extensibility, making it easy to manufacture components and satisfying the needs of architects and structural designers.

Typical use of stainless steel

Most use requirements are to preserve the original appearance of the building for a long time. When determining the type of stainless steel to choose, the main consideration is the required aesthetic standards, the location of the corrosive atmosphere and the cleaning system to be used.

However, other applications increasingly seek only structural integrity or impermeability. For example, roofs and side walls of industrial buildings. In these applications, the owner's construction cost may be more important than aesthetics, and the surface may not be very clean.

304 stainless steel works well in dry indoor environment. However, in rural and urban areas to maintain their appearance outdoors, they need to be cleaned frequently. In heavily polluted industrial and coastal areas, the surface can be very dirty and even rust. However, in order to achieve aesthetic effect in outdoor environment, it is necessary to use nickel stainless steel. Therefore, 304 stainless steel is widely used in curtain wall, side wall, roof and other building purposes, but in the serious erosion of industrial or Marine atmosphere, it is best to use 316 stainless steel.

Stainless steel sliding door

The advantages of using stainless steel in structural applications are well recognized. Several design criteria include 304 and 316 stainless steel. Because "duplex" stainless steel 2205 combines excellent atmospheric corrosion resistance with high tensile strength and elastic limit strength, it is included in the European standard.

The product shape

In fact, stainless steel is manufactured in all standard metal shapes and sizes, and there are many special shapes. The most common products are made of sheet and strip steel, and special products are also made of medium thick plates, for example, hot-rolled structural sections and extruded structural sections. There are also round, oval, square, rectangular and hexagonal welded or seamless steel tubes and other forms of products, including sections, bars, wires and castings.

Surface condition of stainless steel

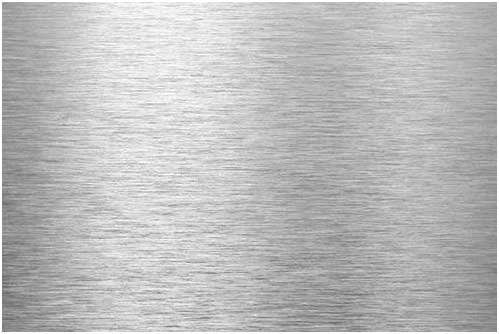

As will be discussed later, a variety of commercial finishes have been developed to meet architects' aesthetic requirements. For example, the surface can be highly reflective or matte; They can be glossy, polished or embossed; It can be colored, colored, electroplated or etched on the surface of stainless steel, and can also be brushed to meet the various requirements of designers on the appearance.

It is easy to maintain the surface state. Only occasional rinsing will remove dust. Due to good corrosion resistance, it is also easy to remove graffiti or similar other surface contamination.

Surface Finish

Surface Treatment

Mirrored

Brushed

Sandblasted

Etched

Titanium.

Embossed

Wood Grain Pattern

Black Titanium

Wood Grain Pattern

The packing way

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:What are the shipping ports?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Q:What is your working time?

A:In general, our online service time is Beijing time: 8:00-22:00, after 22:00, we will reply to your inquiry during the next

working day.

Products are widely used in construction, machinery, coal mining, chemical industry, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction and other manufacturing industries

The corrosion resistance of stainless steel coils decreases as the carbon content increases. Therefore, the carbon content of most stainless steels is low, up to 1.2%, and some steels have a low ωC (carbon content) of even less than 0.03% (such as 00Cr12). The main alloying element in stainless steel coil is Cr (chromium). Only when the Cr content reaches a certain value, the steel has corrosion resistance. Therefore, the goods Cr (chromium) content of at least 10.5%. Stainless steel coil also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

Most of the requirements for use are to maintain the original appearance of the building for a long time. In determining which type of goods to choose, the main considerations are the required aesthetic standards, the corrosiveness of the local atmosphere and the cleaning system to be used. However, other applications are increasingly seeking structural integrity or impermeability. Examples include roofs and sidewalls of industrial buildings. In these applications, construction cost to the owner may be more important than aesthetics, and the surface may not be very clean. The use of 304 stainless steel coils in dry interior environments is quite effective.

Weldability. Different product uses have different requirements for weldability. A class of tableware generally does not require weldability, even including some cookware companies. However, most products require raw materials with good weldability, such as second-class tableware, insulation cups, steel pipes, water heaters, water dispensers, etc.

Corrosion resistance. Most stainless steel coil products require good corrosion resistance, such as Class I or Class II tableware, kitchen utensils, water heaters, water dispensers, etc.

Polishing performance. In today’s society, stainless steel coil products in the production process are generally polished, only a few products such as water heaters, drinking fountains, etc. do not need to be polished. Therefore, this requires raw materials with good polishing performance.

1. The need for pre-treatment

Pretreatment is an important treatment step before the surface of

stainless steel coil parts enter surface treatment (including pickling,

chemical polishing and electrochemical polishing, electroplating,

passivation, black coating, coloring, chemical treatment, etc.). During

the forming process of goods parts, the surface may adhere to oil

stains, burrs, rough surfaces and oxides. Therefore, before surface

treatment, oil stains, burrs, uneven surfaces and oxides must be removed

in order to obtain subsequent satisfactory results through processing.

2. Treatment of removed dirt

Stainless steel coil surface pretreatment in the need to remove the dirt

can be divided into two categories: organic and inorganic substances.

(1) organic dirt. Including mineral oil (such as diesel, oil, paraffin,

gypsum, etc.) and animal oil, vegetable oil (such as soybean oil,

camellia oil, rapeseed oil, lard, butter, etc.). These oils are mainly

from the stainless steel coil zero cattle processing process used in the

lubricant. , cutting oil, quenching oil, polishing paste and polishing

paste, and fingerprints.

(2) Inorganic dirt. Including dirt, dust particles, oxides and other

contaminants generated during the heat treatment process.

3. Pretreatment steps for stainless steel coil parts

(1) The surface is mechanically leveled. Eliminate the roughness of the

stainless steel coil surface, through mechanical polishing and grinding

to achieve a surface finish.

(2) Degreasing. Remove the surface oil and dirt.

(3) Acid washing. Remove the oxides on the surface.

(4) Weak corrosion. Activates the surface to be treated, removes the

surface passivation film, and exposes the metal crystal structure.

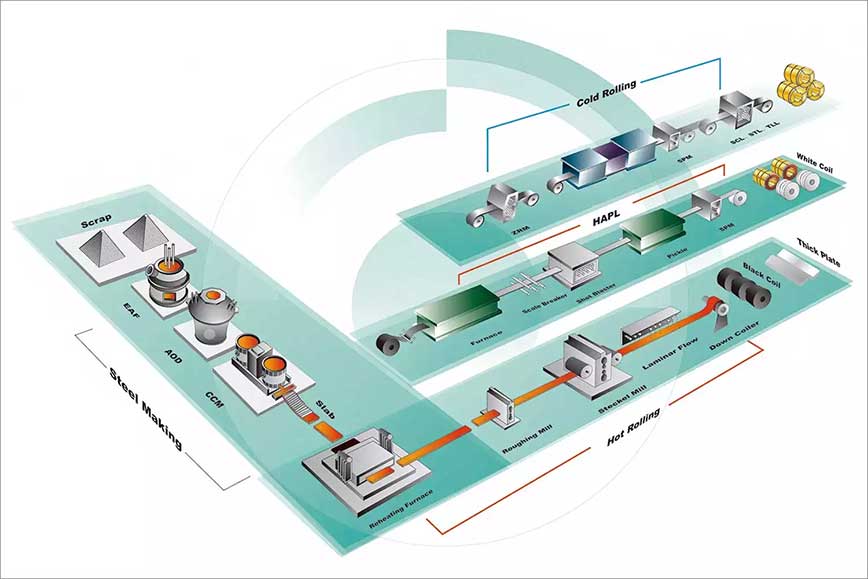

Stainless steel is a high-alloy steel, with a large resistance to rolling deformation. In order to carry out high-efficiency and high-precision rolling, rigid rolling mills should be used, generally multi-roller cold rolling mill.

Special welding process is also a feature of cold-rolled stainless steel coil production.

In the production process of cold rolled stainless steel coil, the raw material (hot rolled coil) should be annealed, intermediate annealing should be carried out in the cold rolling process, and the final product should be annealed, so annealing is an important part of the production.

Cold-rolled stainless steel is a high-grade steel products, there are strict requirements for surface quality. Not only are metallurgical defects caused by the previous process not allowed, but also obvious defects caused by the cold rolling process.

Send your inquiry / assessment to Us. Anything need us ,please don’t hesitate contact us here! we will keep it secret for you !

Send your inquiry / assessment to Us. Anything need us ,please don’t hesitate contact us here! we will keep it secret for you !